![]()

|

|||||

When measuring the vibrations transmitted to the hand-arm system, it is important to fix the accelerometer on the vibrating surface as firmly as possible, preferably using a screw, avoiding the use of magnets or glue, if possible.

To fasten the accelerometer, use a tensile tester and apply the fastening torque recommended by the manufacturer. An excessive fastening could break the sensor.

The presence of the accelerometer should not influence the grip and working modes normally used by the operator.

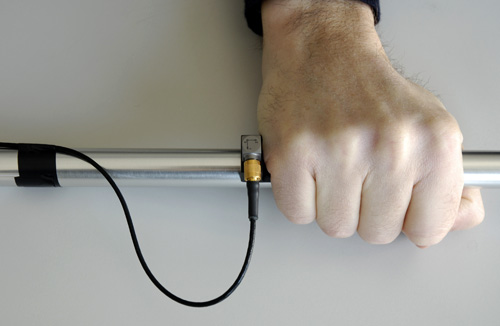

When the tool handle is coated with a resilient material, generally to ease the operator's grip, it is preferable to use a metallic adaptor to be fixed to the handle using strips, or set between the operator's hand and the handle. In this case, you should minimize the distance between the accelerometer and the handle, and make sure that the adaptor is firmly fixed to the handle. You can use strips (plastic, pull or metallic strips).

If you need to fix the adaptor to a handle coated with a resilient material, you should tighten the strips so that the material cannot be compressed further. However, if the machine manufacturer expressly used the resilient material to reduce the vibrations transmitted to the hand-arm system, a full compression could give an over-estimation of the acceleration transmitted to the hand. In this case, the adaptor should be fixed using fabric strips so as not to excessively compress the handle coating.

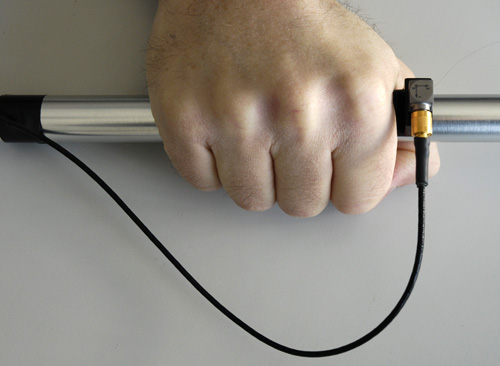

If the adaptor is inserted between the operator's hand and the handle, you just need to fix it using pull strips. The position of the accelerometer should be as close as possible to the center of the hand.

In case of adaptors with the sensor installed on the side, you need to repeat the measurement twice, positioning the accelerometer on both sides of the hand. Then you should use the average value.

|

|

The position and mounting technique selection is done after assessing the tool usage mode and the possible impact on the operator's movements. To minimize the interference with the operator, you also need to assess the position of the connection cables between the accelerometer and the instrument.

If you are using a monoaxial accelerometer, you should orient the sensor along the axis of greater exposition. When you use a triaxial accelerometer, the orientation is not important as all the axes have the same weight in the calculation of the vector acceleration. In any case, it is better to note the position, orientation and mounting technique of the accelerometer.

The cables of the accelerometers should not be pulled or bent, particularly near the sensor. They also should not be free oscillating to avoid fake results in the detected signal (triboelectric noise).

Therefore you need to fix the cables near the transducer, e.g. with adhesive tape.

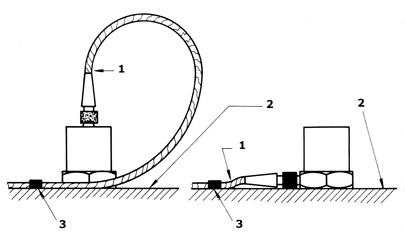

The following picture show two accelerometers: the first has an axial output connector, the second a radial connector.

1. The connection cable should not be pulled or bent.

2. Vibrating surface.

3. The cable should be fixed to the vibrating surface with adhesive tape.

Below, you can see some commonly used mounting techniques (please see a detailed description of the various adaptors below):

Glue or magnetic base: it ensures a good frequency response. The contact surface should be flat and clean.

Metallic adaptor with metallic or plastic strip: it can be fixed easily and adapts well to the handle.

Adaptors for the handle or for the hand: it has a known frequency response. It allows using mechanical filters. But it can be fixed only in limited positions and can condition the tool operation.

Mounting with screws: it ensures a good frequency response. It allows using mechanical filters. It is difficult to realize. In case of a pneumatic tool, you can compromise its functioning.

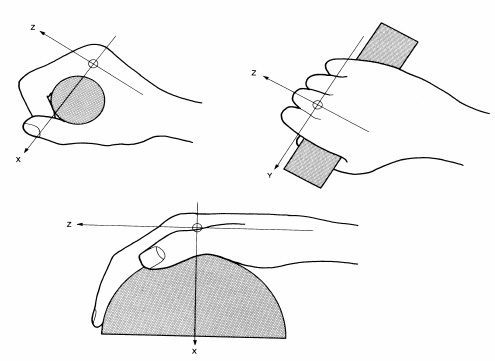

The norm ISO 5349 prescribes, generally, the orientation of the reference system according to which the three components of the vector acceleration are detected:

X axis orthogonal to the hand palm;

Y axis parallel to the hand palm and orthogonal to the Z axis.

Z axis parallel to the forearm bones;

The directions along the axes are irrelevant for the measurement.